Stretch

Automac 40

Automac 40 has been designed with the aim of providing the best performance in terms of reliability, speed (up to 40 ppm, with parameter adjustable according to specific requests of the production) and appearance of the product to meet the needs of large retailers and packaging centers. Its version with double reel of film and the properties of self-diagnosis allow an almost continuous production and maximum flexibility in the use of the film, with two reels of the same type or even of different types for alternate productions.

The speed of Automac 40 is adjustable to allow the machine to manage every type of product. In addition, if the trays are not present on the feed or arrive intermittently, the packaging machine automatically blocks all operations while waiting.This drastically reduces the consumption of electricity and limits mechanical wear to a minimum, allowing to decrease the frequency of maintenance

White and red meats, pork, fish, cheese, fruit, vegetables…: Automac 40 can package any food compatible with stretch technology and neutral or printed film, which enhances the appearance of fresh packaged foods making them more inviting once exposed in the store. Thanks to Fabbri Group’s historical experience in the production of both packaging machines and food films, Automac 40 provides maximum results in combination with Fabbri Group’s stretch films, but it can boast excellent performances even with the films of all the major producers on the market.

Automac 40 also guarantees excellent packaging with every type of tray, regardless of the following parameters:

- Material (expanded polystyrene trays, rigid, vegetable or compostable)

- Shape and dimensions (small catering trays or large trays)

- Colour (coloured or transparent trays)

In order to guarantee the maximum protection and preservation of the product, the packaging system with Automac 40 takes special care of closing the film along the underside of the tray: The outlet sealing tape is designed to optimize the sealing of the film without overheating either the tray or the product

Automac 40 characteristics

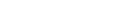

Easy in-line installation

The sturdiness, reliability, flexibility and ease of integration of Automac 40 make it an ideal packaging machine for high productivity. The feeding of the machine is specifically designed to measure the irregular arrival of trays and therefore to be inserted in line without the aid of timing belts.

Double reel

The double film reel, with the self-diagnosis properties of the packaging machine, allows Automac 40 to produce almost continuously, with a minimum of occasional interruptions.

Control panel with color touch screen monitor

Automac 40 can manage up to 29 wrapping programs, ensuring customized programming that no packaging machine can approach. The standard 7'' monitor can be easily replaced with the 10'' monitor as an option, which provides advanced information with a user-friendly interface. The diagnostic system integrated with the control panel ensures complete control of the machine and allows you to quickly detect any anomalies.

Quick change of reel

In Automac 40, the film reel can be easily replaced in just 45", ensuring an almost immediate restart of production. This time can drop to less than 30" thanks to the optional "Second reel support". In addition to the configuration of the wrapping machine, also the low weight of stretch film reels produced by Fabbri Group, which always have an optimized thickness-performance ratio with consequent savings and benefits also for the environment, further facilitates the replacement.

Accessories and options

Automac 40 can be equipped with input extensions and output roller conveyors that allow it to find the best integration with tray feeding and unloading systems. In addition, it is possible to equip it with photocells and connections that allow it to interact easily and safely with portioning machines and weight-pricing equipment.

Optimal ratio of performance and consumption

In case of absence of product, the machine stops automatically, with a drastic reduction of consumption and wear detectable over time.

No need for compressed air

All Automac 40 drives are electric: no compressed air is required and there are no compressors on board the machine.

Maximum safety for the operator

Moving, hot or sharp parts are protected by security devices that cannot be bypassed and therefore remain inaccessible.

A single supplier for the entire packaging system

Automac 40 is part of a fully integrated solution provided by Gruppo Fabbri, a single partner for machines, software, films, technical assistance and spare parts.

Try Automac 40 with the following Fabbri Group films:

by

by