Stretch

Biobased Star Film

Fabbri Group is committed to offering safe, competitive and reliable solutions for a satisfactory food storage, investing in the continuous improvement of performance and sustainability.

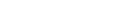

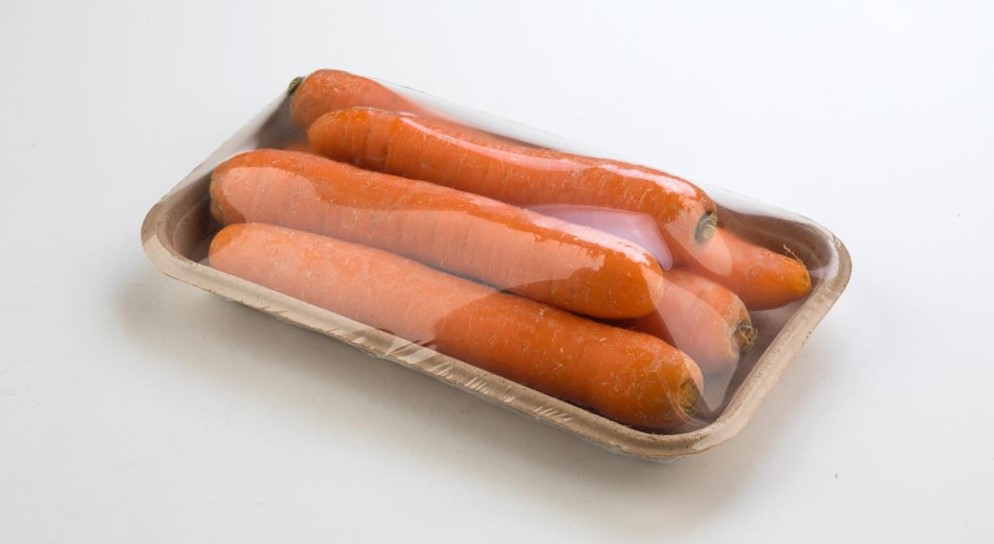

With the development of BIOBASED STAR FILM, we focused on the production of a film allowing to reduce the greenhouse gas emissions produced by the realization of films with components from fossil origin, while maintaining the high performance of plastic films to all effects.

With BIOBASED STAR FILM Fabbri Group contributes concretely to the Sustainability Report of industrial and retail companies, offering a reduction in the use of raw materials from fossil sources in favor of non-fossil ones, in response to the growing demand from increasingly sensitive consumers for environmental protection.

Its high ironing performance allows to minimize the amount of product used to produce the packaging, thus ensuring, in addition to economic savings, also a reduced environmental impact. This aspect is further improved when BIOBASED STAR FILM is used in synergy with Fabbri wrapping machines.

Available in different bands and thicknesses, BIOBASED STAR FILM allows the customer to choose the optimal tool to package his product, ensuring a refined appearance to the packaging, intended for the main distribution and merchandising channels on the market and, finally, to the final consumer.

BIOBASED STAR FILM is certified “OK-biobased®” by TÜV Austria and can be printed in four-colour process up to 10 colors with digital clichés for better brand and product promotion. The Graphic Office of Gruppo Fabbri is available to identify and develop, in synergy with the customer, the most suitable layout to enhance the packaged food and support its sales.

BIOBASED STAR FILM characteristics

Certificate "OK-biobased®"

BIOBASED STAR FILM is certified "OK-biobased®" by TÜV Austria through the C14 isotope survey method, which determines the percentage of carbon from renewable raw materials on the total organic carbon (% bio-based carbon).

Recyclable within the production cicle

The recyclability within the production cycle of BIOBASED STAR FILM is more than 99%.

Sustainable and performing

BIOBASED STAR FILM is the perfect and sustainable solution for automatic packaging and high productivity, with excellent unwinding properties, wrapping capacity of the packaged product ("cling" effect), cutting and welding, and characteristics of antistaticity and high mechanical strength.The ideal combination of BIOBASED STAR FILM is on the automatic stretch machines produced by Fabbri Group, but it still achieves optimal results even on all the most popular packaging machines on the market.

Printable

Like standard PVC/PE stretch films, BIOBASED STAR FILM can be printed in up to 10 colours in four-colour process with digital plates.

Food contact

BIOBASED STAR FILM, in both neutral and printed form, is fully compliant with current legislation on materials in direct contact with food.

Reach e CLP conformity

Its production and the raw materials used are in compliance with all related laws at European and national level, including the Food Contact Law. REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and CLP (European Classification Regulation,labelling and packaging of chemical substances and mixtures) ensures that SVHC (high-risk substances according to the REACH Regulation) are not used.

by

by