TopLid

High productivity and ease of use are the main features of TopLid, Gruppo Fabbri’s ultra-compact automatic tray-sealing machine.

This machine guarantees the packaging of all types of fresh and very fresh food products; in particular, meat packaging is made easier thanks to its typical patented gas exchange process.

TopLid stands out for its easy format changeover due to the development of an extremely light and handy punching for the operator.

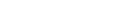

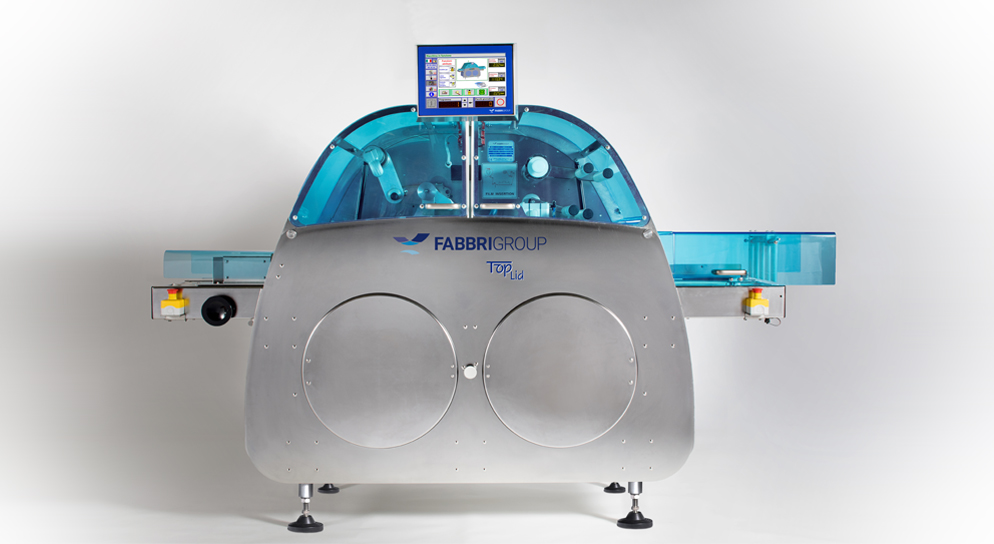

TopLid is available in the standard version, with the typical transparent blue carter, or also in the full-inox version, ideal for the most demanding working environments in terms of production cadence and climatic conditions.

Hypermarkets, packaging centers and industry are the ideal final destinations for this heat-sealing machine made by Gruppo Fabbri.

TopLid is manufactured in full compliance with EU Directive 2006/42/EC, as attested by the independent certification body MTIC INTERCERT, voluntarily involved by Gruppo Fabbri in order to ensure with maximum transparency the safety of its traysealers.

Video

Characteristics

Minimum footprint, maximum productivity

TopLid reaches a maximum packaging speed of 40 ppm in the double row version, and is the only tray-sealing machine to guarantee such a level of performance with the same footprint (footprint of about 1.6 m 2).

Patented gas exchange

TopLid does not require vacuum pumps or other expensive systems to manage the gas mixture even in the presence of high percentages of oxygen. This automatic tray-sealing machine is in fact equipped with an innovative patented gas exchange process, through which it is able to manage gas mixtures with O2 residues down to 0.3%.

Fast, easy and safe format change

With TopLid it is possible to carry out the format change in less than 4 minutes, easily and in total safety. The operation can be set on the touch-screen monitor, which will illustrate all the steps to be performed. In order to prevent errors in advance, the machine will also monitor the various actions carried out in succession by the operator. The machine's design also ensures that the operator's hands or other parts of the body can never come into contact with critical and potentially dangerous parts of tray-sealing machine, such as welders and knives, thus guaranteeing maximum safety for the operator during the format change process. The low weight of the punching allows the operator to handle it easily without having to use a trolley to carry out the format changeover.

Single or double row configuration

TopLid can be configured in single or double row, depending on the application. Converting the machine is extremely simple and simply requires changing the punching tool and the program of use. In this way the machine will be able to pack different types of trays at different speeds, optimizing consumption.

Two carter variants

To meet all the needs and requirements of the customer, the TopLid tray-sealing machine is available in two versions: blue plexy carter and inox steel carter. In both cases the machine has soft lines, with no sharp edges or corners where dirt or processing residues can get stuck, for the maximum safety of the operators and the end customer.

Touch screen monitor

TopLid is equipped with a color touch-screen monitor, with a multilingual, simple and intuitive interface, able to manage all the functions of the machine.

Excellent sealing

TopLid uses the most popular barrier films on the market, guaranteeing excellent sealing even at maximum speed, in compliance with the highest safety standards. The traysealer guarantees ideal performance with PELid, the range of lid films for tray-sealing machines developed by Gruppo Fabbri in different references, each with its own characteristics and specificities (PELid 22, PELid 22 AD, PELid 37, PELid 37 AD, PELid 45).

Variety and sustainability first

TopLid is able to use all the most common trays intended for tray-sealing machines up to the most current sustainable solutions on the market today. Unlike the main shuttle bar machines, thanks to its automatic feeding mechanism TopLid does not require trays to be pre-positioned or spaced at the infeed. Moreover, for this machine, even heights are not a problem: the tray-sealing machine is able to simultaneously handle the same format in different heights thanks to its innovative tray loading system.

Even for overflowing products

Packaging overflowing products, like all those foods that exceed the edge of the tray, is not a problem for TopLid: through the optional designed specifically for this purpose, TopLid guarantees the packaging of this type of products through MAP technology.

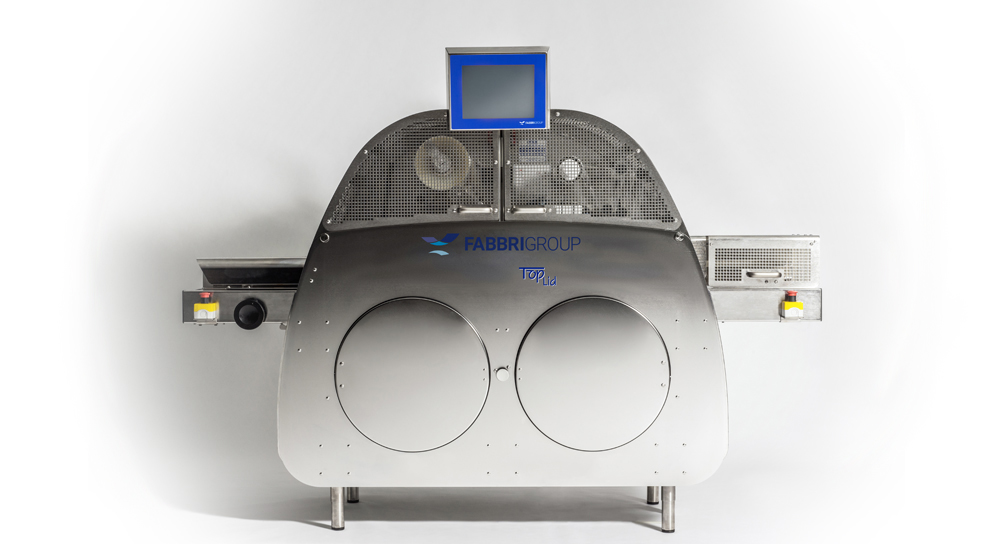

Optimal accessibility in complete safety

In line with all the machines manufactured by Gruppo Fabbri, TopLid guarantees various access points to its various internal mechanical parts through the opening half-domes, the two front panels and the guard on the machine exit. The tray-sealer presents high standards of speed and ease also for cleaning and maintenance operations. The panel containing TopLid's electrical, electronic and pneumatic units has an IP54 protection rating and is located at the rear of the machine for total protection.

Exuberant product, overflowing solution

TOPLid can package trays with overflowing products, like all those products that for presentation or management reasons need to rise above the ideal edge of the tray itself. Thanks to the dedicated option, TOPLid can offer a solution in protective atmosphere with the appealing appearance of freshness. It is also special in this.

Try TopLid with Gruppo Fabbri’s barrier and high barrier films:

by

by