Reading time 1’45”

PVC has always been regarded as a resource-efficient material by experts in the field.

Made from salt (57%) and oil (43%), it’s far less oil dependent than other major thermoplastics.

PVC has proven to be a very robust and energy efficient product in a wide range of applications, also thanks to optimal raw materials and energy employment during its production, which also prevents natural resources depletion.

It’s also highly durable and energy-efficient across a range of applications which makes for an effective use of raw materials and avoids unnecessary depletion of natural resources.

Viewed across its life cycle, PVC is highly competitive against alternative materials in terms of its environmental impact. In many cases, it shows advantages both in terms of total energy consumption and lower CO2 emissions.

Furthermore, only PVC allows to vary its formulation, in order to improve technical performances while, at the same, leaving safety and healthiness unscathed.

This is the context within which VinylPlus places itself.

VinylPlus is the voluntary sustainable development programme of the European PVC industry. It aims at creating a long-term sustainability framework for the entire PVC value chain.

The regional scope of this 10-year programme (2011-2020) is the EU-28 plus Norway and Switzerland.

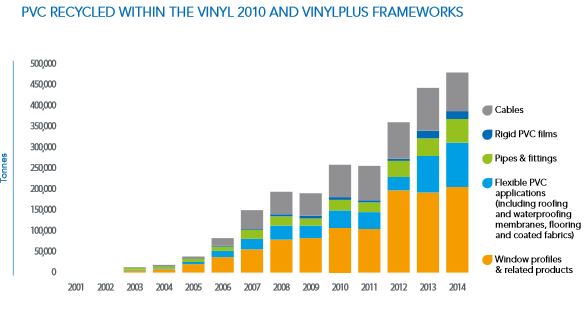

VinylPlus is a natural continuation of its predecessor Vinyl 2010 and moves forward thanks to the open dialogue it creates between industry, NGOs, regulators, public representatives and the end-users of PVC.

It’s main objective is the development of operative mechanisms for the improvement of the eco-sustainability of PVC.

For 2015, VinylPlus has proposed 5 fundamental goals, which Fabbri Group has adopted as its own:

1) Controlled management of the life cycle to recycle up to 800,000 tonnes per year by 2020.

Fabbri Group allocates to external recycling 100% of all its waste products (209 tonnes in 2014).

2) Zero accidents during transportation.

Fabbri Group‘s major suppliers adhere to the VinylPlus programme in order to reach this objective.

3) The sustainable use of additives and the elimination of lead stabilisers by the end of 2015.

The stabilisers used by Fabbri Group have never contained lead.

4) Sustainable energy use and consumption reduction.

To lower environmental impact, Fabbri Group is directing its efforts toward raising energy use efficiency, which will positively influence its film LCA results, consistently with VinylPlus program.

5) Sustainability awareness through the involvement of the stakeholder.

Fabbri Group production sites are ISO 14001:2004-certified. Vignola premises are also registered with EMAS, certified by The Ministry of Environment Technical Committee.

For Fabbri Group, participation in VinylPlus is the logical consequence of the company’s own system of values, which places respect for the consumer and the environment as a core credo for their activity.

Purchasing food wrapped in PVC that is produced consistently with VinylPlus program principles is an added value Fabbri Group offers its business partners, who in turn can guarantee secure and innovative eco-sustainable packaging technology to their own end users.

More info on:

vinylplus.eu

pvc.org

minambiente.it

by

by