Stretch

Automac Industrial

Automac Industrial is high-productivity wrapping machine (up to 55 ppm, with adjustable parameter according to specific production requests) of the FABBRI HYBRID range, which introduces for the first time in the packaging world a new standard based on:

- Packaging sustainability and versatility: Automac Industrial is able to use any type of tray (plastic, bioplastic, cardboard, wood pulp, cellulose pulp…) and extensible film (traditional films, biobased films, compostable films, in neutral or printed form combining them with traditional or compostable labels

- Saving: Automac Industrial has been designed to guarantee maximum savings even in terms of energy consumption, machine wear and for ordinary and extraordinary maintenance

- Production quality: with specific accessories, Automac Industrial is optimized to guarantee the best wrapping quality and the best production performance

- Connectivity: Automac Industrial can easily connect to factory ERP and MES systems

- Industry 4.0: Automac Industrial meets all the requirements of the “Industry 4.0” standard

Automac Industrial can realize all this thanks to advanced technology accessories:

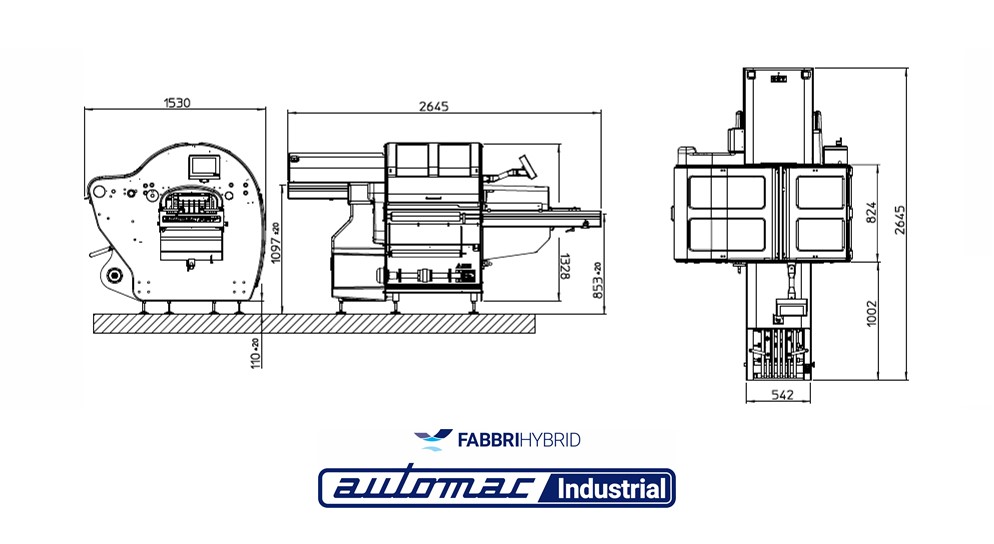

Automatic presser

The automatic presser is automatically positioned at the height specified in the selected wrapping program:

→ No human intervention needed

→ Quick and easily format change

Automatic carriage adjustment

The carriage also automatically positions itself to the width specified in the selected winding program, with the following advantages:

→ No human intervention needed

→ Quick and easily format change

Side clamp

Automac Industrial’s side clamps allow the film to be held in longitudinal direction, obtaining a stretch on 4 sides:

→ Saving Packaging Materials

→ Better Wrapping Quality

Output product control system

The output product control system allows to stop the machine in case of accumulation of the output trays:

→ Lower energy consumption

→ Maximum line efficiency

Monitor 10’’

The 10" touch-screen monitor allows navigation in the machine menu to display and set programs and recall or save them. The parameters and programs can also be connected to the ERP and MES systems of the factory:

→ Easy to use

→ Programmability

→ Industry 4.0

Device connection

This option enables the exchange of signals between Automac Industrial and the rest of the machines in line, also providing the input for connection to the local LAN:

→ Production data monitoring

→ Data management

→ Study and statistical processing of data

→ Interconnection between the machines of line

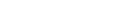

Automac Industrial characteristics

Easy in-line installation

The robustness, reliability, flexibility and ease of integration of Automac Industrial make it an ideal packaging machine for high productivity. The feeding of the machine is specifically designed to measure the irregular arrival of trays and to be inserted in line without the aid of timing belts.

Optimal ratio of performance and consumption

In case of absence of product, the machine stops automatically, with a drastic reduction of consumption and wear detectable over time.

Quickly reel replacement

In Automac Industrial, the film reel can be easily replaced in just 45", ensuring an almost immediate restart of production.. This time can drop to less than 30" thanks to the optional "Second reel support". In addition to the configuration of wrapping machines, also the low weight of stretch film reels produced by Fabbri Group, have an optimized thickness-performance ratio with consequent savings and benefits for the environment, further facilitates the replacement.

No compressed air needed

All Automac Industrial drives are electric: compressed air is not required and there are no compressors on board the machine.

Maximum safety for the operator

Moving, hot or sharp parts are not accessible but protected by security devices that cannot be bypassed.

One supplier for the entire packaging system

Automac Industrial is part of a fully integrated solution provided by Fabbri Group, a single partner for machines, software, films, technical assistance and spare parts.

Try Automac Industrial with the following Fabbri Group films:

by

by