Machines

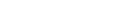

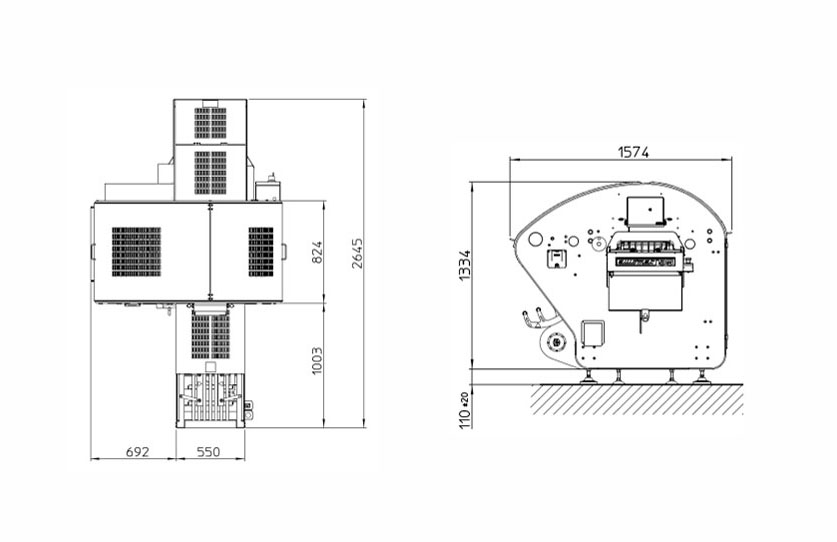

Automac 75 e Automac 95

Automac 75 and Automac 95 are the Fabbri Group’s answer to the increasing volume of requests for increased performance of packaging centres and industrial production lines. Evolution, in technical, functional and aesthetic terms, of Automac 55 Più, with the same footprint on the ground, increases its performance in terms of robustness, resistance and reliability, maintaining flexibility in the format change and increasing the maximum packaging speed up to 75 or 90 packs per minute respectively..

The new touch-screen monitor also allows an easy and immediate dialogue with the machines, facilitating the packaging and the maintenance operations.

The elegant lines of Automac 75 and Automac 95, entirely made of stainless steel and aluminium, cover an advanced uncoiling and film tensioning system, designed to guarantee a perfect printing centering and a fluid and fast packaging process.

Designed with particular attention to the details and needs of the operator, Automac 75 and Automac 95 are at the top of current safety standards and offer a comfortable and protected working area. Automac 75 and Automac 95 are in compliance with Community Directive 2006/42/EC, as certified by the independent certification body TÜV Intercert.

Please contact us for more info!

High-speed

Both high-speed automatic stretch machines, Automac 75 and Automac 95 differ primarily in production performance: while Automac 75 reaches 75 ppm, Automac 95 offers the most demanding customers a maximum speed of 90 ppm. These parameters can be amended according to specific production requirements.

Plug ‘n’ Pack

Automac 75 and Automac 95 are powered at 400 V without any need for compressed air: easy to connect, quiet to use.

Safety first

Automac 75 and Automac 95 have been designed in compliance with the most stringent safety regulations in place: access to the internal parts is regulated by the micro-switches of the machine inspection housings, which block the operation in case of opening.Rounded lines and the absence of sharp edges also minimise the consequences of accidental impacts.

Practical, functional, hygienic

Periodic cleaning and regular maintenance of Automac 75 and Automac 95 are significantly facilitated by 8 access points to the internal parts of the machine, such as, in particular, the sliding casing above the feeding belt, useful for timely removal of the product, the ejector and the lift, which can be quickly disassembled and washable separately, and the opening of the gull wing housings, which is mostly appreciated even in cases where the available space is reduced. Under the lift, moreover, there is nothing: this ensures the maintenance of perfect hygiene during production and facilitates the cleaning operations to the maximum.

Always perfectly in line

Automac 75 and Automac 95 can be equipped with feeding extensions, unloading roller conveyors, photocells and connections for the best integration in line with other machines, both in and out.

Films, trays, products… No problem!

Thanks to the numerous dedicated options, Automac 75 and Automac 95 can guarantee the perfect wrapping of any tray, regardless of shape, material or size, and the type of film used, neutral or printed. In particular, the automatic upper ejector allows it to maintain a high packaging speed even in the presence of high trays (up to 200 mm with Automac 75!) or with overflowing products.

High integrability

??

Everything under control

Thanks to the new control panel with touch-screen monitors, Automac 75 and Automac 95 offer up to 29 different modifiable wrapping programs to meet the production needs of each customer. The integrated diagnostic system also allows you to quickly detect and resolve any anomalies.

Simple

??

Reliability

Automac 75 and Automac 95 have been designed in compliance with the most stringent safety regulations in place: access to the internal parts is regulated by the micro-switches of the machine inspection housings, which block the operation in case of opening.Rounded lines and the absence of sharp edges also minimise the consequences of accidental impacts.

Energy saving

??

by

by